Technical Support

Centrifugal Casting Technology of Large Double Flanged Copper Tile

- Categories:Technical Support

- Author:

- Origin:

- Time of issue:2023-04-06

- Views:185

(Summary description)Shandong Zhengxiang Industrial and Mining Equipment Co., LTD. Centrifugal casting large copper sleeve, copper sleeve material covers tin bronze, aluminum bronze, lead bronze, high force brass and other copper base alloy materials, welcome to figure customized production.

Centrifugal Casting Technology of Large Double Flanged Copper Tile

(Summary description)Shandong Zhengxiang Industrial and Mining Equipment Co., LTD. Centrifugal casting large copper sleeve, copper sleeve material covers tin bronze, aluminum bronze, lead bronze, high force brass and other copper base alloy materials, welcome to figure customized production.

- Categories:Technical Support

- Author:

- Origin:

- Time of issue:2023-04-06

- Views:185

Centrifugal casting is widely used in the casting industry, divided into cantilever centrifuge, vertical centrifuge, roller centrifuge, etc., suitable for the production of straight sleeve and single flange sleeve (tile) class, production of double flange tile products including flange step size of the product is more difficult, low qualified rate, high reject rate, production efficiency, products prone to flange crack phenomenon, Or in the process of production casting mold running phenomenon, resulting in serious product eccentricity or internal hole processing amount is small, there is porosity, slag phenomenon.

Analysis of centrifugal casting technology of double flange copper tile (sleeve)

Centrifugal casting double flange copper tile (set) class, such as casting into a straight set class, casting weight increase too much in more than 2/3, processing allowance is too large, resulting in an increase in cost.

Our company in view of this situation, from the original casting straight sleeve class, into casting double flange tile (set) class, through continuous research and improvement of the process, solved the problem of casting double flange tile class casting difficulty, but also achieved good results.

Centrifugal casting double flange copper tile (set) technology key, is the shrinkage of the casting parts caused by crack phenomenon, and centrifuge mold deformation, in the process of casting water, water leakage caused by weightless damage centrifuge equipment, or eccentric casting hole processing amount is insufficient, processing can not cause porosity, slag defects.

Improvement of centrifugal casting technology for double flange copper tile (sleeve)

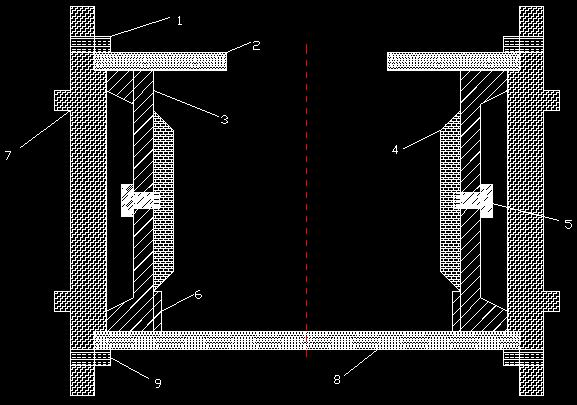

Centrifuge mold is divided into outer mold and inner mold, centrifugal casting double flange tile type inner mold is the combination of two sets of mold.Figure:

1. Front file pin 2. Front baffle 3. The whole package 4. Internal mold 5. Fix the screws 6. Fix the straight mouth 7. External mold 8. Tailgate 9. Rear file pin

1. The whole set of internal mold is made of cast steel 35, and the wall thickness is 60mm. The inner mold material is made of ferritic gray cast iron, and the wall thickness is 1.1 times that of the casting wall. In order to facilitate the internal mold and casting molding, the drawing inclination is 1:100. The inner die must be machined on both internal and external sides, with the deviation of inner and outer circle concentricity less than 0.1mm, inner surface roughness Ra 3.2µm and outer surface roughness Ra 12.5µm. The inner and outer die assembly clearance is 2.5mm.

2. The key of centrifugal casting large double flange copper tile is to accurately calculate the safety Angle of shrinkage, and make the transition Angle between the flange and the cylinder less than the safety Angle. For the flange and the body diameter of the product is relatively large, the casting joint is prone to crack phenomenon, so the processing of the mold, to turn into a large bevel.

3. The internal die is sawed apart, milled out the Yin and Yang groove, the straight mouth is 6-8mm, polished clean, combined without gap, and welded tightly with flat iron.

4. After the two sets of molds are processed, they are combined. The drilling and tapping on the whole set of molds are evenly divided into 4 pieces. The gap between the inner mold and the inner set is within 1mm.

Double flange copper tile (sleeve) centrifugal casting technology

1. According to different casting materials, the preheating temperature of the mold is different. The tin bronze mold is preheated to 130-150 ℃. For brass, high-force brass and aluminum bronze materials, the mold is preheated to 200-250 ℃.

2. Tin bronze 5-5-5, tin bronze 6-6-3, pouring temperature at 1030-1060 ℃, tin bronze 10-1 pouring temperature at 1010-1040 ℃. Brass pouring temperature in 1000-1030℃, high force brass pouring temperature in 1020-1050℃, aluminum bronze pouring temperature in 1160-1200℃.

3. Tin bronze mold spraying zirconium powder alcohol coating, natural cooling 50-60 ℃, such as mold temperature is too high, casting will produce hot eye defects, mold temperature is too low, casting appearance will produce slag inclusion defects. Hanging bag, pouring bag, casting flow brush lead powder preheating, can not have moisture, such as moisture, casting will produce porosity defects. Brass, high force brass, aluminum bronze material mold brush lead powder coating, brushing should be uniform, paint is not too thick, in 1-2mm is appropriate.

4 With cantilever centrifuge, centrifuge outer die to find the table, find the highest point, mark, mold, the highest point up.

5 According to the size of the inner diameter of the casting and the calculation formula to adjust the centrifuge speed.

6 at the beginning of pouring, in order to form the entire inner surface in the metal type, follow the principle of fast after slow, start pouring, pouring speed should be fast, let the pouring speed and the growth rate of the metal solidified layer to adapt, the pouring process, liquid copper can not have interval, cut-off flow, or flow rate is too slow phenomenon, such as pouring speed is too slow, casting will produce slag defects.

7 centrifugal casting, the two ends of the casting slag is more serious, so according to the size of the product and material shrinkage, reasonable design of the size of the mold. When purchasing the mold and processing the mold in advance, the length of the mold should be properly extended and the two end faces of the casting are easy to nest slag.

8. Tin bronze 5-5-5, tin bronze 6-6-3, brass, high force brass, aluminum bronze material castings, when the casting flow is selected, the front opening flow is selected for pouring. According to the length of the casting, the flow depth in the front baffle 1:5 ratio adjustment. Tin bronze 10-1, the selection of gap type low opening flow for pouring, the length of the gap should account for about 2/3 of the length of the casting.

9. The size of the unilateral interval between the pouring flow and the inner hole of the front baffle mold is 50-100mm. The size of the unilateral interval between the inner hole of the casting blank and the inner hole of the front baffle mold is not less than 50mm.

Centrifugal casting example of double flange copper tile (sleeve)

In the casting of Aluminum and Zhejiang Tongli customer double flange watts, the material is ZCuAl10Fe3, the pre-furnace spectrum test, in line with the national mechanical property testing standard (GB/T1176-2013). As shown in Figure 2:

|

National standard components, mechanical properties |

|||||

|

Elements |

Copper Cu |

Aluminum Al |

Iron Fe |

|

|

|

Range % |

Allowance |

8.5 -- 11 |

2 -- 4 |

|

|

|

Mechanical properties |

Tensile strength /Rm |

Yield strength /Rp0.2 |

Elongation /% |

Brinell hardness /HBW |

Casting method |

|

490 |

180 |

13 |

100 |

S |

|

|

540 |

200 |

15 |

110 |

J |

|

|

540 |

200 |

15 |

110 |

Li, La |

|

The drawing size of the product is φ835*40/φ690*631*770/φ835*40, the number of products is 4, the weight of the finished product is 510kg, our company uses the idler centrifuge casting, the jacket is φ1200mm, the centrifugal speed is 780 RPM, after the casting is completed, take out the casting, after processing, The flange of the first casting has cracks and defects. After the processing amount of the flange is enlarged, the casting is cast again. The casting is in good condition after processing, and the last 3 pieces are without defects. The centrifugal casting of the double flange tile is successful.

References:

1.Casting Manual Casting Non-Ferrous Alloys 3rd Edition, 2011

2."Casting copper and copper Combination" GB/T1176-2013

3."Large double flange copper tile centrifugal casting technology" Citic Heavy Industry cast iron branch: Meng Hongchao Etc.

Scan the QR code to read on your phone

Service Hotline:

FAX:0537—4401368

Cell phone:13375371599

E-mail:qfzxgk@163.com

QQ:2531928993 、2621161245

Want want:qfmkgkpjjg

Address: Xiyuan 7th Road, Gongye 1st Road, West Economic Development Zone, Qufu City

Copyright © 2020 Shandong Zhengxiang Industrial and Mining Equipment Co., Ltd. All Right Reserved 鲁ICP备19036021号-1